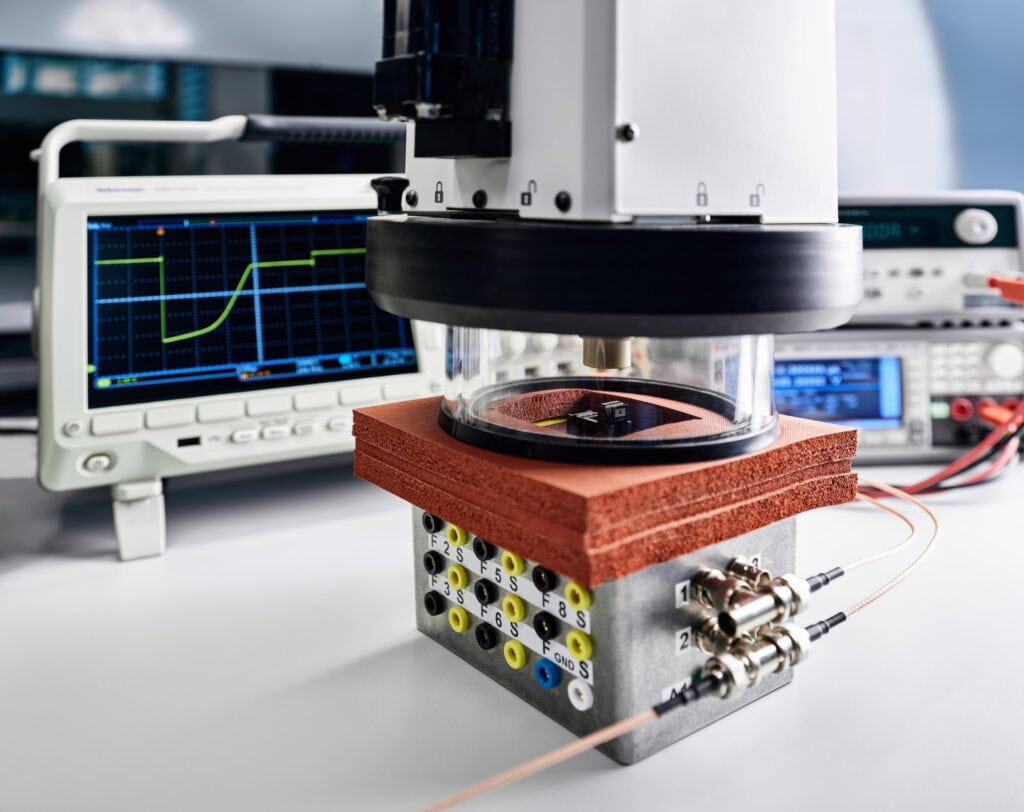

From programming to long-term storage: Semitron’s highly qualified test and programming house offers end-to-end solutions for electronic components.

We provide a comprehensive range of services designed to optimize semiconductor workflows, ensure the quality and authenticity of components, and deliver scalable solutions for both small and large-scale production. By leveraging our advanced technology and industry expertise, customers can streamline their processes, safeguard product quality, and focus on their core innovations.

This test house is unique in Germany. No other distributor offers its customers in-house test services in addition to component supply.

The service you mentioned is not included? In addition to the services presented here, we are happy to support you with the following:

Do you need something else?

Our flexibility is our strength.

We will clarify free of charge how we can best assist you.

We help companies tackle the challenges of modern semiconductor development and production. By working with us, engineers gain access to extensive expertise, cutting-edge methodologies, and a full suite of services designed to enhance product quality, reduce costs, and accelerate time-to-market. Our services span multiple stages of the component lifecycle—from initial programming to long-term storage. We provide a one-stop solution for all semiconductor-related needs, allowing engineering teams to focus on innovation and design while knowing their component processes are handled by industry experts with a proven track record.

Stay up to date with the latest semiconductor and programming developments without the need for continuous internal investment.

Eliminate high capital expenditures and ongoing costs for equipment maintenance and in-house programming teams.

Easily adapt to changing project requirements, from small-batch to large-scale production.

Strict testing and authentication processes ensure high-quality, genuine components that meet or exceed industry standards.

Outsourcing these specialized services allows your engineers to focus on core tasks such as design and innovation.

From initial programming to long-term storage, Semitron provides end-to-end services covering the entire lifecycle of semiconductor components.

Custom solutions and support for a wide range of devices allow engineers to work with various component types without needing in-depth programming expertise for each one.

State-of-the-art authenticity testing and long-term packaging services protect against counterfeit parts and premature component failure.

Our test house services comply with the strict regulations of industries such as aerospace and defense.

Please provide details such as the type and quantity of components, the specific services required (e.g., programming, testing, tape-and-reel), special requirements, and your desired turnaround time when requesting a quote.

The project duration varies depending on the scope and complexity of the required services. Standard programming and testing typically take 1-2 weeks. For more complex or high-volume projects, we provide a detailed timeline during the quoting process.

Yes, we offer expedited services for time-sensitive projects. Please inform us about your urgency when requesting a quote, and we will do our best to meet your deadline.

We implement strict technical and organizational security measures, including secure facilities, controlled access, and confidentiality agreements. We are also open to discussing specific security requirements for your project.

Absolutely. Our services are scalable to handle both small-batch prototypes and large-scale production. We will work with you to determine the most efficient approach for your needs.

All our services follow optimized processes and include strict quality controls and mechanisms. From incoming inspection to in-process controls and final quality assurance, we ensure reliability. We use risk assessment tools such as Failure Mode and Effects Analysis (FMEA), follow continuous improvement processes (KVP), and focus on systematic error prevention. Our systems and procedures ensure full traceability.

If we encounter any issues during the process, we will notify you immediately and discuss the best solution. Our goal is to resolve problems efficiently while ensuring transparency throughout the process.

No. We provide test house services for all components, regardless of whether they were purchased through our distribution services or supplied by you.

Semitron’s unique value is its combined expertise in distribution and test house services. As an authorized distributor, we offer a wide range of components from leading manufacturers such as ADI, Microchip, and Honeywell. But we go beyond just supplying components. Our state-of-the-art facilities and test house services ensure that your components function perfectly in your specific application. Throughout the entire process, you’ll benefit from our team’s in-depth knowledge and support.

Our test house services support a wide range of industries and businesses in the semiconductor and electronics sector. Here are just a few examples:

Manufacturers of Electronic Devices Can Leverage Semitron’s Programming, Testing, and Tape-and-Reel Services to Optimize Their Production Processes and Ensure Component Quality.

These industries require highly reliable components and often long-term storage solutions. Semitron’s authenticity testing and long-term packaging services with nitrogen flushing are particularly valuable in preserving component integrity over extended periods.

Given the critical nature of medical electronics, these companies can benefit from Semitron’s rigorous testing and authentication services to ensure the reliability and safety of their components.

Industrial equipment manufacturers can use Semitron’s services to ensure the longevity and reliability of their components, especially for systems requiring long-term support.

Companies manufacturing products for critical applications can utilize Semitron’s environmental stress tests and long-term reliability assessments to ensure product performance under various conditions.

Organizations maintaining legacy electronic systems can rely on Semitron’s services to test and program components that may no longer be widely supported.

These organizations can access advanced programming and testing capabilities without making significant capital investments in equipment and personnel.

We would be happy to answer your questions in a personal conversation. Use our contact form or send us an email to – we look forward to hearing from you!

Three Steps to First-Class Results

Request Initial Consultation

Analysis of Your Requirements

Offer & Execution

Or get in touch with one of our contacts directly:

You are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information